The complexity of our business is a result of the committed relationship between key variables, such as the capacity to produce a wide variety of products, manufactured to the highest quality standards, and our satisfaction of regulatory demands associated with registration processes.

We work tirelessly to promote a sustainable and safe operation and we are able to produce and deliver a wide range of products with quality recognised by our customers thanks to our modern manufacturing facilities, the qualifications of our employees and the fact that we have one of the best formulation development laboratories in Europe - giving us a competitive lead in the analysis of raw materials, active ingredients, finished and semi-finished products.

Modern and Sophisticated Plants

In Setubal, Portugal, we manage modern and sophisticated facilities which are chiefly dedicated to our crop protection business. These units are fully adapted to our business needs, combining flexibility, efficiency, and environmental safety, ensuring the best safety conditions for our employees.

The plants consist of four completely independent sites:

Fungicide and Insecticide Plant

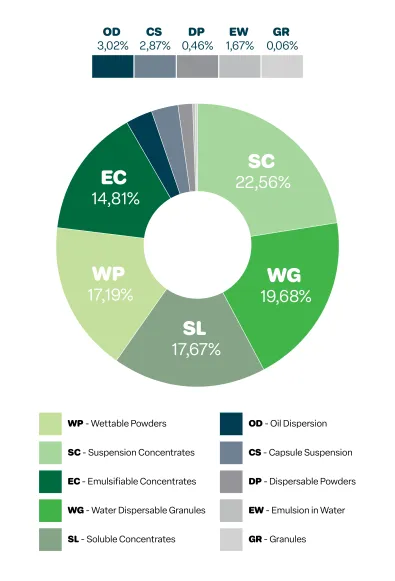

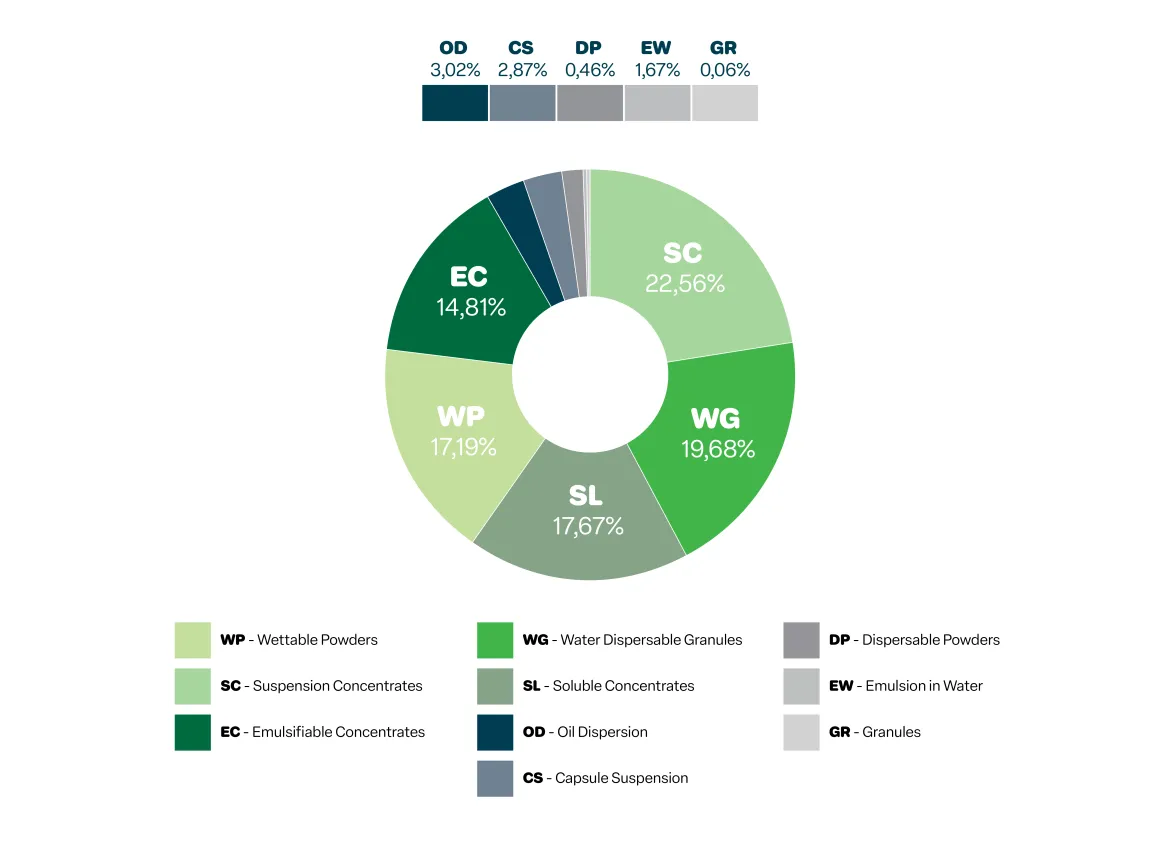

This unit produces agrochemical products in a solid state in the form of Dispersible Powder (DP), Wettable Powder (WP) and Water Dispersible Granules (WG) both by spray drying and extrusion processes. Similarly, agrochemicals products in a liquid state are manufactured in the form of Emulsifiable Concentrates (EC), Soluble Concentrates (SL), Suspension Concentrates or Flows (SC), water-in-oil emulsions (EO), Capsule Suspension (CS) and also mixed formulation of CS and SC (ZC). Different types of manufacturing processes are used depending on the type of formulation, the active substance, and the physical-chemical properties.

Different packaging techniques are used to pack agrochemical products in their solid and liquid state, depending on their final formulation.

Herbicide Plant

Our herbicide plant unit produce agrochemicals solutions in various forms: Suspension Concentrates (SC), Soluble Concentrates (SL), Suspoemulsion (SE), Emulsifiable Concentrates (EC), Capsule Suspension (CS) and Oil Dispersion (OD). This unit also has a dedicated facility for glyphosate production, starting from the amination process till the formulated product with a total capacity of approximately 11 million liters.

The manufacturing processes and packaging techniques are similar to the ones described for fungicide and insecticide plants.

Sulphonylurea Plant

In this unit we formulate and package sulphonylureas in both solid (WG) and liquid (OD) states. As a safety precaution, these facilities operate using clean rooms that are separated depending on the processes. These facilities are fully dedicated, separated, and isolated from other production units.

Formulation Expertise

Through constant improvement and adaptation to market trends and needs, at ASCENZA we have developed robust knowledge in the field of formulation.

This has been pivotal to our strategy to add value to our key molecules, which is a significant competitive advantage in terms of our differentiation effort, with the goal of better serving our clients and farmers.

Today, in Setubal, we work with modern formulation types, even the most technically demanding.

To support our business model, laboratory capability is a key element of our strategy.

On the one hand, it ensures maximum operational quality standards, from the raw materials to the end product. This is achieved through our GLP-certified quality control lab.

On the other hand, our labs also support all of our R&D developments and regulatory activities. Supported by a broad range of international certification standards, our lab capacity covers the following key business needs:

- Physical-Chemical GLP Lab

- Pesticides Residue GLP Lab

- Efficacy and Residues Trial Units (GEP and GLP)

- Formulation Development Lab

- Screening and Synthesis Lab

- Synthesis Pilot Unit