ASCENZA and The Environment

At ASCENZA we care for the Plants, the People, and the Planet and therefore there are multiple initiatives in which we are investing in our resources to ensure that we are following the best environmental protection practices, ensuring long-term planet protection.

Zero Gas Project

Today, at ASCENZA, through multiple workflows, we are already able to identify the required investments to meet one of our key objectives: promoting energy efficiency and installing renewable energy sources in our industrial plant in Setúbal, Portugal.

Zero Gas is a project that precisely targets the implementation of seven measures based on introducing the state of the art in energy efficiency, updating technological supplies, and implementing renewable energy sources, such as photovoltaic energy.

This project is now planned to be implemented in the Setúbal industrial facilities (except for the sulphur plants) by 2026, which will lead to a reduction in ASCEBZA's carbon footprint by approximately 40% (660 tCO2e), allowing this site to improve its status as a benchmark in energy management.

Biodiversity

In Setúbal, Portugal, ASCENZA’s plant has an adjacent location to the Natural Estuary of Sado Reserve (RNES), which is precisely a protected area for its avifauna biodiversity.

To help preserve all this surrounding natural area we now have a rainwater collecting system, which allows us to collect and monitor rainwater to detect any environmentally harmful active substances, thus ensuring safe treatment and discharge.

In this context, we also carry out regular water monitoring measurements of these substances in the waters surrounding the production unit's estuary.

Water Management

ASCENZA assumes today several practices to reduce water consumption, promoting better water management throughout the life cycle of products.

Furthermore, in our factory in Setúbal, we have implemented practices that aim to save and maintain water quality. These practices are related to:

- Our Rainwater Treatment System - with a total capacity of 11,000 m3 and associated with the city's waste-water treatment plant, this system allows us to have zero direct environmental impact.

- And the way we treat the industrial equipment washing - the water used to wash production equipment is used in future formulations of the same product, which allows us to reduce the amount of wastewater and reduce the consumption of fresh water.

Currently, the contamination of water sources by crop protection substances can be avoided in 80 to 90% of cases by carrying out appropriate farming practices, and that is why this awareness and trainings are so relevant.

Packaging collection for recycling

Plastic is a threat to the planet's health, particularly to the oceans. The use of this material is becoming unsustainable due to the harmful effects it has on the environmental balance and, in just five years, the presence of plastic in the oceans has become a global concern that has led to several actions aimed at reducing plastic use worldwide.

However, in the case of crop protection products, packaging left in the environment can lead to the contamination of soil and groundwater by pesticides. In addition, there is a risk that empty containers could be reused to store food and water, which could lead to unwanted poisoning.

A packaging management system can minimise these risks and is part of 'life cycle thinking' as addressed in the International Code of Conduct on the Distribution and Use of Pesticides.

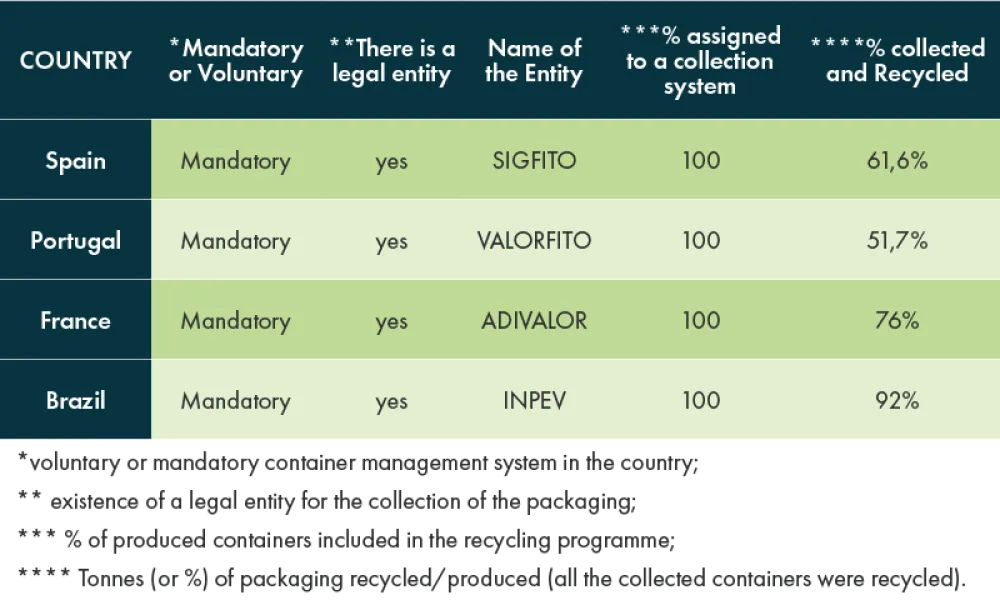

Depending on the country, a packaging management system may be voluntary or mandatory. It is common practice to set up a legal entity to administer it. In many schemes around the world, the administrative body is a non-profit company set up and financed by the suppliers of plant protection products.

Our companies in the different countries where we are active provide collection points for used containers for farmers, offering them the opportunity to send their containers for recycling.

We, therefore, share some of our results.